In the metalworking, carpentry, and manufacturing world, one unsung hero has made waves for decades: the belt sander. Known for its uncanny ability to shape, polish, and smooth with speed and efficiency, the belt sander is the “smooth talker” of the industrial world, a machine that brings precision, finesse, and power to the table.

The Belt Sander: What It Brings to the Workshop

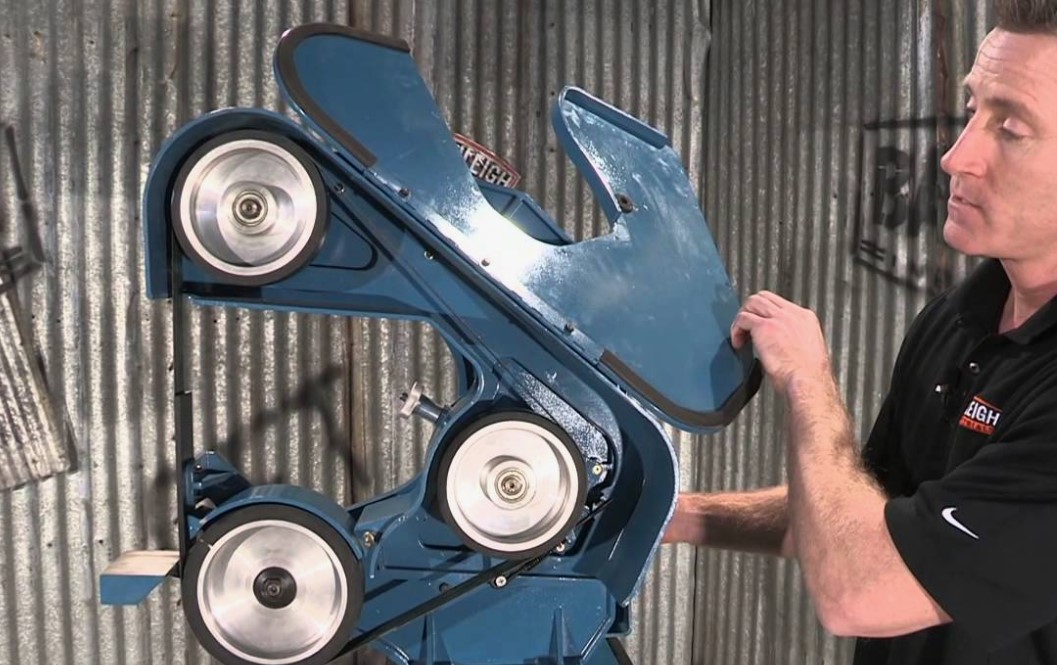

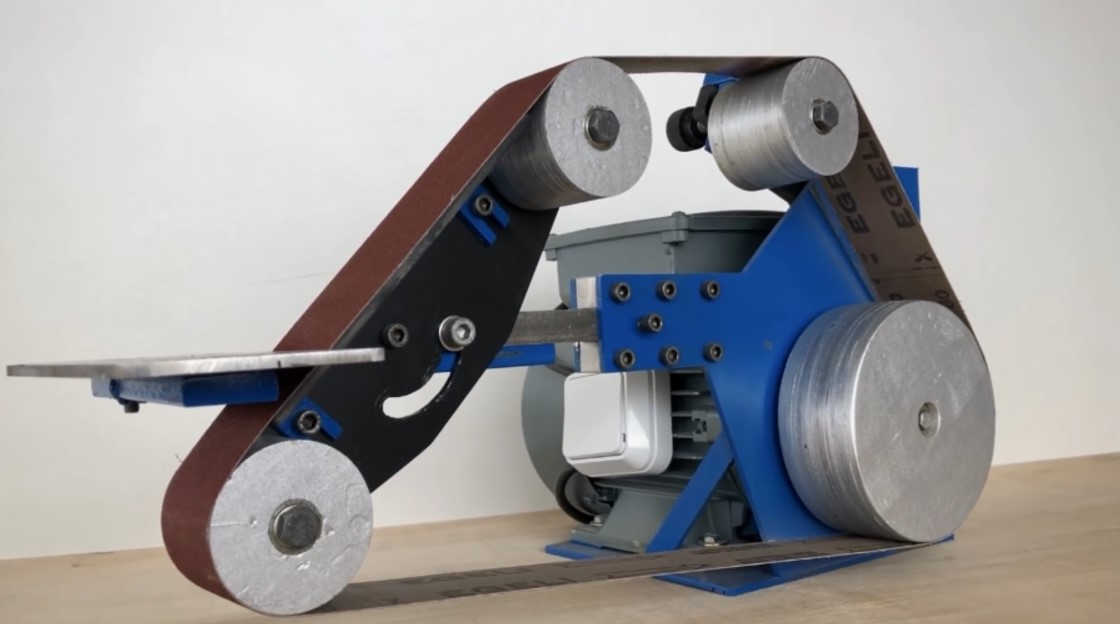

Belt sanders are trusted allies for craftsmen, woodworkers, and industrial workers when smoothing out rough edges or achieving that perfect finish. They operate by running a continuous loop of sandpaper over two drums, providing a constant abrasive surface to sand down materials easily. But this isn’t just any sander—belt sanders bring brute power and refined control.

Belt sanders come in different sizes, but their typical applications involve flattening rough surfaces, removing unwanted material, and preparing surfaces for finishing touches. They’re commonly used in settings that require fast material removal, making them essential in industrial sectors like woodworking, metal fabrication, and automotive bodywork.

Belt Sanders: A Versatile Tool in a World of Precision

The versatility of a belt sander is what sets it apart from other sanding tools. In an industrial setting, it can handle everything from heavy-duty sanding on large, flat surfaces to delicate refinements on more intricate projects. Here’s a breakdown of its key uses in industrial and workshop environments:

Surface Preparation

Before applying finishes like paint, stain, or lacquer, a belt sander is frequently used to smooth down surfaces. According to industry sources, approximately 70% of workshop specialists believe that surface preparation is essential to guaranteeing a high-quality finish.

Material Shaping and Sculpting

Belt sanders are particularly well-liked for swiftly removing substantial amounts of material. They are essential for professions like carpentry, where employees use them to precisely and effortlessly shape wood or smooth down sharp edges.

Removal of Rust and Paint

Belt sanders are vital for eliminating old paint layers and rust in the metalworking and automotive sectors. A belt sander can transform a rusty, worn-down metal surface into a clean, paint-ready piece with the correct sandpaper grit.

The Power of Grit: Choosing the Right Sandpaper

The type of sandpaper attached to a belt sander also influences its performance. Grit size determines how aggressive or fine the sanding will be, making it crucial to match the grit to the task.

For example, 40—to 60-grit sandpaper is ideal for heavy material removal, while 100—to 150-grit works well for general-purpose sanding. A fine 180—to 220-grit paper is ideal for a smooth, polished finish. Selecting the right grit can boost productivity and save material costs, as fewer passes are required to achieve the desired result.

Belt Sanders and Productivity: A Statistical Perspective

In industrial settings, time and productivity are everything. According to a 2022 report from the Manufacturing Productivity Index, companies using belt sanders to prepare materials saved up to 30% in production time compared to companies using traditional or hand sanding methods. The belt sander’s speed and efficiency directly contribute to this time savings, making it a cost-effective choice for many workshops and factories.

Another study from the Industrial Tools Association (ITA) revealed that companies employing automated or semi-automated belt sanders experienced a 15% reduction in labor costs due to the machine’s quick setup and straightforward operation. These numbers highlight why belt sanders are considered essential in high-volume production environments.

Safety First: Using Belt Sanders Responsibly

While belt sanders are powerful tools, they are highly risky if improperly handled. The same power that makes them efficient can also make them dangerous. Here are some quick safety tips that should always be followed in industrial settings:

Proper PPE (Personal Protective Equipment): Goggles, gloves, and dust masks are essential when using belt sanders to protect from flying debris and fine dust particles.

Stable Work Surface: Always ensure the workpiece is firmly clamped or held down to avoid accidents or material shifting.

Correct Tensioning: Ensure the sanding belt is properly tensioned to prevent slippage or snapping.

Dust Collection: Many belt sanders are equipped with a dust collection bag. Proper dust collection helps maintain visibility and reduces the risk of inhaling harmful particles.

Industrial safety boards, such as OSHA, emphasize that dust collection and respirator masks reduce airborne particle exposure by over 50%, helping workers stay safe in sanding environments.

Innovation in Belt Sanders: Smart Technology for Precision and Efficiency

As with many industrial tools, belt sanders are evolving with technology. Today’s belt sanders have variable speed control, electronic feedback sensors, and digital tracking systems to keep the belt centered. Sensors adjust the belt speed based on pressure and material, allowing for a smoother finish and extending the belt’s life.

High-end models offer programmable settings to meet precise specifications, which is invaluable for workshops with multiple material types and thickness requirements. Additionally, some models have automatic shut-off features when overheating is detected, helping to extend the machine’s life and enhance workplace safety.

According to industry analysts, companies that invested in modern belt sanders with programmable settings and digital controls reported a 25% increase in productivity and a 10% reduction in equipment maintenance costs within the first year of use.

Belt Sanders as Sustainable Solutions

As industrial practices shift towards sustainable solutions, belt sanders join the movement. Many belt sanders are now built to be energy-efficient, consuming less power without compromising performance. Furthermore, using reusable belts with durable coatings means fewer replacements and less waste, aligning with eco-conscious business practices.

Some manufacturers are developing belts from recycled materials, reducing the environmental impact of their production. As of 2023, about 15% of American industrial businesses claimed reduced energy expenses and improved brand recognition due to implementing eco-friendly belt sanders. Because of these changes, the belt sander is a productive tool in today’s eco-conscious industry.

Conclusion: Belt Sanders, The Essential Industrial Smooth Operator

From rough-hewn wood and stubborn metal surfaces to delicate edges that require finesse, belt sanders remain the true smooth talkers of industrial settings. Their history and evolution demonstrate a blend of practicality, innovation, and versatility that few tools can rival. With modern advancements enhancing safety and precision, belt sanders continue proving their value across various industries, helping workers achieve efficiency without compromising quality.

So, whether preparing wood for a high-end cabinet, shaping metal components, or simply polishing a surface to perfection, the belt sander is an indispensable asset. A tool that speaks the language of precision and power, the belt sander isn’t just a tool; it’s the smooth operator every industry needs.

Cyclist, follower of Christ, ukulelist, Mad Men fan and Guest speaker. Operating at the fulcrum of aesthetics and elegance to craft meaningful ideas that endure. I work with Fortune 500 companies and startups.